Protecting house and home

For Justin Leonard, studying water tanks, fences, windows and timber decks is not an indiscriminate or arbitrary choice. It is all part of one methodical scientific investigation – one compelling narrative.

“It’s about identifying gaps in our understanding,” Leonard said, “and working to have that complete story.”

Mr Leonard, a Bushfire CRC Project Leader and Research Scientist with CSIRO Sustainable Ecosystems, has spent the past seven years on a body of work that ultimately helps people end up with homes that can better stand up to bushfires. His work is often readily adopted into construction and planning educational materials, but he points out that actual building codes are limited in their applications, and a good deal of his work is therefore centered not simply on the design of homes that can withstand exposure to bushfire but making effective choices for minimising the exposure the house receives in the first place.

Mr Leonard, a Bushfire CRC Project Leader and Research Scientist with CSIRO Sustainable Ecosystems, has spent the past seven years on a body of work that ultimately helps people end up with homes that can better stand up to bushfires. His work is often readily adopted into construction and planning educational materials, but he points out that actual building codes are limited in their applications, and a good deal of his work is therefore centered not simply on the design of homes that can withstand exposure to bushfire but making effective choices for minimising the exposure the house receives in the first place.

“The Building Code of Australia, which calls up the Australian Standard on building in bushfire-prone areas, is limited to the design of the building envelope and its proximity to the garage and its proximity to the bush, so it’s a fairly simple combination of elements that only paint part of the picture to the suite of things that are going to play out in causing the potential failure or survival of the house,” Leonard said. “You can imagine there must be other ways to manage or regulate the landscape when needed.”

Water tanks, for instance, were a concern for Leonard given the regular observations he made during post-bushfire surveys and investigative work, where catastrophic rupturing of tanks was commonplace. Fibreglass tanks failed extensively in these surveys, and when they failed they would impact adjacent structures.

“There were a lot of water tank failures, and a large number of those failures were associated with people expecting or wanting to use a water supply as part of their defence, either as a spray system for the house during the event, or an expectation they could come out and hose things down as part of their plan.” This problem was often compounded, he said, by a failure of the mains water infrastructure during fire events, and for some time afterward. “But it wasn’t understood or known what the intricacies were of selecting the right water tank and putting it in the right position in the landscape.”

Enter a rigorous testing model, and the result is a body of work of great use to the public in bushfire prone areas. The research provided solid evidence about the limits of each of the tank types, as well as guidelines for where tanks should be placed with regard to fuel sources (including other tanks).

Metal tanks invariably performed well. Concrete tanks even better, particularly in-ground concrete tanks. Plastic (or polyethylene roto-molded) tanks burned down to the water line or failed completely.

“A new area of related research might come from information gathered from Black Saturday, where pumps and piping networks failed,” Mr Leonard said. “There’s a real lack of understanding about the specific performance limits of engine driven pumping systems. [Investigating those performance limits] would be a nice body of research for informing communities and fire agencies about how to choose, install and protect a piece of critical infrastructure.”

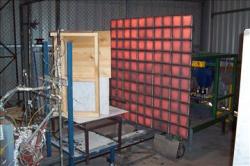

As part of an effort to contribute to that larger body of knowledge, Leonard also explored what happens to windows exposed to bushfire conditions. The area is complex, he said, because there are so many different glazing technologies and framing types, and a wide range of expectations about how well they need to stand up to a given exposure – from preventing embers passing through, to dealing with a certain amount of radiant heat, to standing up to full flame immersion.

The work looked at a variety of popular products and found confident operating ranges for each, compiling a body of information for glazing companies to use to more appropriately target applications, or to inform design solutions in the Building Code.

Plain float glass windows, for instance, do relatively well up to around 12 kilowatts per square metre of radiant heat before they crack. Toughened glass is good to about 40kW/m2, which is quite high (more or less the point of imminent flame contact). Yet toughened glass itself often outperformed the conventional framing system in which they are commonly found, because the conventional seal used to hold the window in place is a polymeric seal, and fails around 30kW/ m2, at which point it melts and burns, dropping the glass inside the frame and allowing flames and embers in at the top of the window.

Plain float glass windows, for instance, do relatively well up to around 12 kilowatts per square metre of radiant heat before they crack. Toughened glass is good to about 40kW/m2, which is quite high (more or less the point of imminent flame contact). Yet toughened glass itself often outperformed the conventional framing system in which they are commonly found, because the conventional seal used to hold the window in place is a polymeric seal, and fails around 30kW/ m2, at which point it melts and burns, dropping the glass inside the frame and allowing flames and embers in at the top of the window.

“There are all kinds of interesting peculiarities, but once you do a lot of tests you get a detailed understanding,” Leonard said. “There’s so much to do in this space. A look into how double-glazing performs. Is a big window more at risk than a small window? There’s always something to investigate.”

Mr Leonard’s field investigations also brought attention to burned-out fences in the landscape, and the typical way that people are building homes in an urbanised setting – with a minimum separation distance from the boundary, meaning fences within a metre or so of the home itself.

That left Leonard and other researchers scratching their heads at how much of a role fences play in threatening houses. Can much be said about fence type (hard wood versus treated pine, for example)? And can fences act as a thermal barrier, limiting the amount of radiant heat that reaches the house?

“We really wanted to answer two questions,” Leonard said. “What risks do fences pose to houses? What type of benefits would fences provide when they’re not burning down?”

One answer that emerged early was that treated pine fences burn down very readily from simple ember build up, even without severe fire weather conditions. “Not only that,” said Leonard, “but the posts were burning through and the fences were falling against the house. The typical height of a fence and proximity of a window meant that the top of the fence could actually smash the centre of the window.”

Metal fencing provided a good barrier that persisted even from a long-term adjacent structural fire. The paint would discolor, but the amount of re-radiation produced was startlingly low and virtually negligible. And for slatted fences, he said, it was as if the fence was not even there, offering no barrier to an advancing flame front.

Metal fencing provided a good barrier that persisted even from a long-term adjacent structural fire. The paint would discolor, but the amount of re-radiation produced was startlingly low and virtually negligible. And for slatted fences, he said, it was as if the fence was not even there, offering no barrier to an advancing flame front.

With the place of decks so prominent in rural Australian home design, it is unsurprising that Leonard’s work on timber decking was also extensive.

“Remember, timber is a very complex material. Then there’s complexity within the deck design itself, and the types of houses and façade configurations that decks are often built against,” he said. “How do decks behave under the multitude of exposures they might be subjected to, from fire fuel build up under a deck, to deposition of burning fire fuel on a deck, to a combination of fire fuel impact and radiant heat? With a huge accumulation of leaves under a deck or somebody storing materials under a deck, the deck almost acts like the slatted fence, where the flames come up through it – it doesn’t act as a barrier at all itself but is in fact an additional fuel load that contributes to the flame.” Leonard looked at the ignitibility of different deck designs and the way deck boards interact with bearers. Building with combustible or non-combustible bearers, capping or no capping, for instance, can have dramatically different consequences.

“Should an ember land between two boards on top of a combustible bearer, you have three ignitable surfaces in close proximity to one another,” he said. “That‘s one of the most ideal configurations to nurture the development and transition of that ember into a fire. When it starts to burn, it’ll involve all of those timber elements, come out over the top, lick underneath and spread over the deck.”

Another particularly fruitful area of study relating to decks came from an investigation into the moisture content of timber decking, and how it varies depending on weather conditions.

Despite the disparate directions Leonard’s research has taken, however, in the end the body of work comes back to that single methodical narrative. Leonard just wants to identify gaps in knowledge, find some answers and help complete the story.

“Ultimately, what I’d like to see is good uptake of the research in planning guidelines in bushfire prone areas, and that the gaps between planning regulation, building regulation and community education are filled,” he said. “Ideally, they actually form a universal combination of treatments that work holistically, so that people can more adequately predict their risk and make decisions based on the potential weakness of their house and property.”

Moisture in timber decking

The more severe the fire weather conditions, the worse the fire – that’s a bit of a no-brainer.

But what people don’t necessarily appreciate, and what has been investigated by Bushfire CRC Project Leader and CSIRO Sustainable Ecosystems Research Scientist Justin Leonard, is the fact that not only is the fire more severe, but assets – like houses – are substantially more vulnerable because of the fire weather.

Stifling hot dry winds that are really low in humidity, and really high wind speeds, said Leonard, have a substantial drying effect not only on the vegetation, but on all of the cured timber elements that houses are made from. In short, Leonard’s work shows there is a huge escalation in vulnerability at the same time as a huge escalation in hazard, and the risk of high loss outcomes is a direct result of this combination.

“Some of the observations we’ve made establishing how low the moisture content actually gets in the timber at the time a fire might arrive are quite startling, and certainly substantially different to the types of assumptions people had been making before when they were designing test methods for understanding how ignitable timber is under certain circumstances.”

Sitting in his office late last year at the CSIRO in Highett, in Melbourne’s south-eastern suburbs, Leonard pulled up a report with a series of line graphs to illustrate the particulars of his point. The graphs charted the moisture content of different timbers as measured during spells of hot weather, and each line looked like a downward-dipping rollercoaster – falling dramatically during the heat of the day, rising gradually during the night (though not as much as usual), then dropping lower still the day after.

“It more or less says it all in one picture,” he said. “When you get a series of hot dry days, you also have hot nights. The nights aren’t particularly humid, meaning the normal recovery period isn’t particularly large, and it ratchets down to having astoundingly low moisture content at the end of the process.”

Mr Leonard’s testing reveals that timber samples researchers might previously have expected to have a moisture content of 10 or 12 percent actually have a moisture content of around four to six percent.

“That’s a huge difference,” he said. “And on top of that, we’re talking about the mean moisture content – the average moisture content in a large piece of timber. But what happens also during the day is that the exposed surface timber is much drier than the average, and the ignitibility and initial rate of combustion of the timber is defined by its effective surface moisture content – not necessarily the average – so the problem is even worse than the picture that’s painted.”

In addition, the graphs do not represent the most severe days of summer. (Tests were conducted during hot spells not associated with any strong bushfires.) And while the tests were conducted on decking, Leonard said the research is relevant to all timber elements on a structure. (Results follow a consistent downward trend whether for jarrah, merbau, black bark, mountain ash or a range of other woods.)

“It’s an unfortunate combination of circumstances, but it’s great to really nut out the fundamentals of what’s going on,” Leonard said. “Performing tests on timber specimens at six percent moisture content instead of 12 will be a fundamental improvement to us understanding and characterising the role of timber in bushfire prone areas.”

By Konrad Marshall, Bushfire CRC Communications Officer

(This article first appeared in the Summer 2009/10 issue of Fire Australia magazine)